Was ist in modularen Hausbausätzen enthalten: Kernkomponenten und Standardleistungen

Standardmäßige Bestandteile modularer Hausbausätze: Vom Fundament bis zum Endausbau

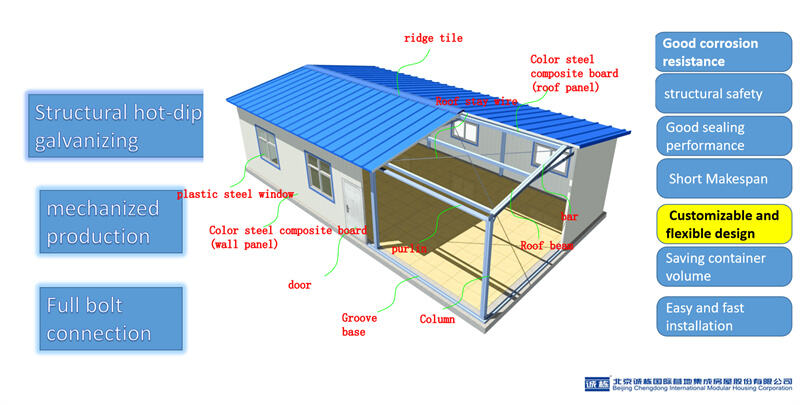

Modulare Hausbausätze liefern den Bauunternehmen im Grunde alles, was sie für einen effizienten Bauprozess benötigen. Die meisten Bausätze enthalten alle wesentlichen strukturellen Komponenten wie Bodenträger, Wandpaneele und die dreieckigen Dachbinder, die man kennt, wenn man Häuser während des Baus betrachtet. Außerdem sind Außenkomponenten wie Verkleidungsmaterial, tatsächliches Dachmaterial und jene modernen energiesparenden Fenster enthalten, die heutzutage jeder haben möchte. Das wirklich Beeindruckende? Dinge wie Wasserrohrleitungen, elektrische Leitungen sowie sogar die Heizungs-, Lüftungs- und Klimaanlage werden bereits im Werk installiert. Dadurch reduziert sich der Arbeitsaufwand vor Ort erheblich. Die Hersteller übernehmen auch die Dämmung, montieren die innere Trockenbauverkleidung und befestigen die Fundamentanker, bevor alles versandt wird. Wie ich aus verschiedenen Fachpublikationen gelesen habe, erfüllen diese vorgefertigten Häuser in der Regel alle örtlichen baurechtlichen Vorschriften und können die gesamte Bauzeit im Vergleich zu herkömmlich errichteten Häusern um ein Drittel bis fast die Hälfte verkürzen.

Wichtige Strukturkomponenten: Rahmen, Wände, Dach und Bodensysteme

Modulhäuser stehen dank sorgfältiger Konstruktion während des gesamten Bauprozesses stabil. Die meisten Rahmen bestehen entweder aus Stahl oder Holz, je nachdem, was sich am besten für das Projekt eignet. Die Wände sind mit einer Dämmung ausgestattet, deren R-Werte zwischen 18 und 25 liegen, wodurch sie im Winter gut dafür sorgen, die Wärme im Gebäude zu halten. Bei den Dächern gestalten die Bauunternehmen die Fachwerke so, dass das Gewicht gleichmäßig über die gesamte Struktur verteilt wird. Die Böden bestehen typischerweise aus OSB-Platten oder normalem Sperrholz in Kombination mit speziellen Konstruktionsbalken, die dort zusätzliche Stabilität bieten, wo sie benötigt wird. Fenster und Türen sind ebenfalls nicht standardisiert, sondern werden so hergestellt, dass bestimmte Ziele hinsichtlich Energieeffizienz erreicht werden. Und bevor irgendetwas die Fabrik verlässt, durchläuft jedes einzelne Bauteil gründliche Prüfungen, um sicherzustellen, dass alle Teile die gemäß der Bauvorschriften festgelegten Anforderungen des IRC erfüllen.

Gängige Typen und Stile von Modulhaus-Bausätzen

Käufer haben heutzutage zahlreiche Stiloptionen auf dem Markt. Denken Sie an traditionelle Ranchhäuser, gemütliche Cape-Cod-Häuser oder schicke moderne Designs. Auch die Größen variieren stark – von etwa 600 Quadratfuß für kleine Cottages bis hin zu über 3.000 Quadratfuß bei größeren mehrstöckigen Immobilien. Viele Hersteller bieten heute standardmäßig offene Grundrisse an, obwohl einige weiterhin auf Einzelmodul-Einheiten setzen. Erweiterbare Konfigurationen werden bei Familien, die später ihren Wohnraum vergrößern möchten, zunehmend beliebter. Für umweltbewusste Käufer gibt es zahlreiche ökologische Optionen. Einige Modelle sind bereits werkseitig für Solaranlagen vorbereitet, andere verwenden durchgängig recycelte Baumaterialien. Es existieren zudem spezialisierte Bausätze für unterschiedliche Klimazonen, die in der Regel robustere Fundament-Systeme und Fenster beinhalten, die gegen Hurrikane oder extreme Wetterbedingungen ausgelegt sind. Die meisten Hersteller empfehlen ihren Kunden, Innenausstattung und Sanitäranlagen bereits während der Bauphase statt nach Fertigstellung individuell anzupassen, was dabei hilft, den Gesamtzeitplan einzuhalten und die Kosten kalkulierbar zu halten.

Außen- und Innenausstattung: Materialien, Qualität und Anpassungsmöglichkeiten

Außenbauteile: Fassadenverkleidung, Dach, Fenster und Türen – Haltbarkeit und Energieeffizienz

Bei Modulhäusern greifen Hersteller oft auf Materialien zurück, die jeder Laune der Natur standhalten können. Denken Sie an Vinyl-Fassadenverkleidungen, die bei Minusgraden nicht reißen, und Metall-Dächer, die sogar orkanartigen Winden trotzen. Die eigentliche Kostenersparnis liegt bei den ENERGY STAR-zertifizierten Fenstern in Kombination mit wärmeisolierten Stahltüren. Diese Bauteile reduzieren Wärmeverluste so stark, dass Hausbesitzer laut aktuellen Branchendaten aus dem Nachhaltigkeitsbericht des vergangenen Jahres durchschnittlich 30 bis 50 Prozent weniger für Heizkosten ausgeben. Außerdem, da alle Endbearbeitungen vor der Montage bereits im Werk erfolgen, besteht keine Gefahr, dass Regen Lackierungen oder andere Oberflächenbehandlungen während des Baus beschädigt.

Innenverkleidungen: Wände, Fußböden, Zierleisten und Einbaumöbel

Zur Standardausstattung der Innenräume gehören vorgefertigte Trockenbauwände, furniertes Massivholz und Keramikfliesenböden für eine schnelle Montage. Millimetergenaues Schneiden sorgt für exakte Passform bei Zierleisten und Einbauregalen. Moderne Bausätze enthalten zunehmend energiesparende LED-Beleuchtung und vorkonfektionierte Smart-Home-Systeme als Standardmerkmale.

Küchen- und Badezimmergrundrisse: Vorgefertigt für Effizienz und Funktionalität

Küchen folgen oft platzsparenden Galley-Designs, während Badezimmer so angelegt sind, dass sie den ADA-Vorgaben entsprechen und den Raum effizient nutzen. Vormontierte Nasswände mit Vorinstallation und gerätefertige Aussparungen beschleunigen die Installation. Laut einer Studie aus dem Jahr 2023 zur Modulbauindustrie verkürzen diese konstruktionsmäßig optimierten Grundrisse die Bauzeit im Durchschnitt um 18 Tage.

Möglichkeiten zur Individualisierung: Ausgewogenes Verhältnis zwischen persönlichen Designwünschen und serienmäßiger Fertigung

Die meisten Fertighäuser basieren auf Standarddesigns, aber Unternehmen führen in der Regel etwa 120 verschiedene Küchenfronten sowie rund 45 Optionen für Außenfarben. Einige Hersteller erlauben es Kunden sogar, Fenster umzupositionieren oder Raumgrößen während des Baus anzupassen, obwohl solche Änderungen normalerweise vier bis sechs zusätzliche Wochen zur Lieferzeit hinzufügen. Laut aktueller Marktforschung aus dem Jahr 2024 erhält etwa drei von vier Käufern genau das, was sie sich wünschen, indem sie Standardkomponenten mit nach der Installation vorgenommenen Ergänzungen kombinieren. Beliebte Möglichkeiten, um die Räume nach Abschluss der Bauarbeiten individuell zu gestalten, sind beispielsweise die Anbringung dekorativer Holzverkleidungen oder die Installation von Smart-Glass-Wänden.

Gründung und Baustellenvorbereitung: Die Voraussetzungen für die Installation eines Fertighauses schaffen

Wichtige Schritte zur Baustellenvorbereitung vor der Lieferung von Fertighaus-Bausätzen

Die richtige Vorbereitung der Baustelle macht den entscheidenden Unterschied dafür, dass die Installation reibungslos verläuft. Dazu gehören grundlegende Maßnahmen wie das Beseitigen von Hindernissen auf dem Boden, die Sicherstellung einer korrekten Neigung der Fläche für die Wasserabfuhr und das Durchführen von Bodenuntersuchungen, um festzustellen, ob der Untergrund das zu Errichtende tatsächlich tragen kann. Laut dem jüngsten Modular Construction Report aus dem Jahr 2024 erfahren die meisten Bauherren auf die harte Tour, dass etwa acht von zehn Projektrückständen darauf zurückzuführen sind, dass jemand überprüft hat, wie gut der Boden verdichtet war. Wasserleitungen, elektrische Anschlüsse und Sickergrube müssen bereits lange vor der Ankunft der vorgefertigten Bauelemente auf der Baustelle installiert werden, da sonst spätere Korrekturen ein Vermögen kosten. Bauunternehmen, die sich Zeit nehmen, alles ordnungsgemäß zu nivellieren, berichten laut Umfragen des National Association of Home Builders von einer Verringerung von Fehlern während der Montage um rund vierzig Prozent.

Gründungsarten für modulare Häuser: Plattenfundament, Kriechkeller und Keller

Modulhäuser verwenden drei Haupttypen von Fundamenten, die jeweils für unterschiedliche Bedingungen geeignet sind:

| Fundamenttyp | Bauzeit | Ideal für | Wichtige Überlegung |

|---|---|---|---|

| Schiefer | 1–2 Wochen | Flaches Gelände | Frosttiefe |

| Kriechkeller | 2–3 Wochen | Regionen mit hoher Feuchtigkeit | Belüftungsanforderungen |

| Keller | 4–6 Wochen | Kältegebiete | Investitionen in Wasserdichtigkeit |

Klimaoptimierte Fundamente, wie gedämmte Bodenplatten, verbessern die Energieeffizienz um 18–22 % (DOE-Daten 2023). Über 60 % der Hersteller verlangen eine endgültige Fundamentprüfung, bevor die Module geliefert werden.

Anpassung der Fundamentanforderungen an klimatische und topografische Gegebenheiten

Schraubfundamente eignen sich besonders gut in Permafrostgebieten, wo Bodenbewegungen stets ein Problem darstellen. In überschwemmungsgefährdeten Gebieten schreiben die Bauvorschriften heute üblicherweise Fundamente vor, die zwischen 30 und 48 Zoll über dem als Basis-Hochwasserstand definierten Niveau liegen. Im Bergbau zeigen Stützmauern deutliche Verbesserungen. Geotechnische Untersuchungen zeigen, dass diese Strukturen etwa 87 Prozent der modularen Baustellen in hügeligem Gelände stabilisieren. Im Süden zeichnet sich ein klarer Trend zur Kombination von Kriechkellern mit Fundamentplatten bei Neubauten ab. Diese hybride Bauweise erhöht nicht nur die Widerstandsfähigkeit gegenüber Hurrikans, sondern verbessert auch die Kühlleistung der Gebäude. Die Kosten variieren jedoch erheblich, um etwa plus/minus fünfzehntausend Dollar, je nachdem, welche Baumaterialien lokal verfügbar sind.

Der Bauprozess: Lieferung, Montage und abschließende Inspektionen

Logistik der Lieferung von Modulhaus-Bausätzen zur Baustelle

Die Lieferung erfordert eine sorgfältige Koordination. Die Module werden sicher verpackt und auf speziellen Anhängern transportiert, wobei die Routen so geplant werden, dass sie den Brückenfreiraum und Straßenbeschränkungen berücksichtigen. Für Kranarbeiten ist in der Regel ein Mindestfreiraum von 50 Fuß erforderlich. Die Lieferungen werden so zeitlich abgestimmt, dass sie mit dem Abschluss der Fundamentarbeiten zusammenfallen, um Witterungsausfällen vorzubeugen.

Montage vor Ort: Verbindung der Module und Abdichtung der Fugen zur Gewährleistung der strukturellen Integrität

Bei der Montage modularen Strukturen positionieren Kräne jedes Modul sorgfältig auf der vorbereiteten Fundamentbasis an exakt berechneten Ausrichtungspunkten. Die Verbindungen zwischen diesen Modulen werden mit dicken Stahlplatten verstärkt, die mithilfe von robusten Befestigungselementen fest verschraubt werden und erheblichen Belastungen standhalten können. An den vertikalen Fugen, wo Wände aufeinandertreffen, tragen die Bauunternehmer geschlossenzelliges Dichtungsschaum auf, um Zugluft zu verhindern und unerwünschte Feuchtigkeit auszusperren. Dachabschnitte erhalten ebenso eine durchgehende Verkleidung, ein Vorgehen, das aus traditionellen industriellen Bautechniken übernommen wurde. Dieser Ansatz trägt dazu bei, sicherzustellen, dass die gesamte Konstruktion genauso gut funktioniert wie herkömmliche Gebäude, die vollständig vor Ort statt teilweise außerhalb des Bauplatzes vorgefertigt errichtet werden.

Endgültige Fertigstellung: Anschluss der Versorgungsleitungen, Inspektionen und Bereitstellung für den Einzug

Sobald die Struktur verschlossen ist, schließen lizenzierte Unternehmer elektrische Anlagen, Sanitär- und Klimatechnik an werkseitig installierte Schnittstellen an. Die örtlichen Behörden führen abschließende Inspektionen durch, um die Einhaltung der IRC-Vorschriften zu überprüfen, und erteilen Nutzungsbescheinigungen nach Durchführung von Systembelastungstests. Eine Studie des NAHB aus dem Jahr 2023 ergab, dass modulare Projekte die Inspektionen aufgrund vorgestellter Komponenten 18 % schneller bestehen als herkömmliche Bauvorhaben.

Berücksichtigung von Bedenken: Strukturelle Leistung und langfristige Haltbarkeit nach der Montage

Unabhängige Ingenieure haben untersucht, wie diese vorgefertigten Häuser bei Erdbeben und starken Winden abschneiden, und festgestellt, dass sie genauso gut funktionieren wie traditionell errichtete Häuser, wenn sie korrekt zusammengebaut werden. Die Mehrheit der Unternehmen gewährt auf ihre Produkte mindestens zehn Jahre Garantie auf strukturelle Integrität. Laut aktuellen Daten aus dem Hausbericht des letzten Jahres von FEMA hatten fast alle Hausbesitzer (rund 93 %) innerhalb der ersten fünf Jahre keine Probleme mit dem Fundament. Regelmäßige Überprüfungen der Verbindungsfugen sowie routinemäßige Abdichtungen an Türen und Fenstern tragen maßgeblich dazu bei, dass diese Häuser auch in den kommenden Jahrzehnten stabil bleiben.

So wählen Sie das richtige Modulhaus-Set für Ihre Bedürfnisse

Bewertung von Grundrissen und Skalierbarkeit für zukünftige Erweiterungen

Bei der Bewertung von Grundrissen ist es wichtig, zu überlegen, ob sie jetzt und auch in Zukunft geeignet sind. Laut den neuesten Wohnungstrends aus dem Jahr 2024 legen fast sieben von zehn Hauskäufern großen Wert auf Räume, die mehrere Generationen unter einem Dach beherbergen können oder einen dedizierten Arbeitsbereich zu Hause bieten. Energieeffizienz sollte heutzutage ganz oben auf der Liste stehen. Denken Sie an Häuser, die mit passiven Solarelementen konzipiert wurden, oder an offene Küchenbereiche, die nicht nur gut aussehen, sondern auch tatsächlich die monatlichen Kosten senken. Und vergessen Sie nicht das tragende Gerüst des Hauses selbst. Prüfen Sie, ob tragende Wände so positioniert sind, dass spätere Erweiterungen sinnvoll möglich sind, etwa ein zusätzlicher Stockwerk oder ein gemütlicher Wintergarten im hinteren Gartenbereich. Diese strukturellen Details mögen auf den ersten Blick unwichtig erscheinen, können aber bei späteren Umbauten Ärger (und Geld) sparen.

Vergleich von Materialqualität, Energieeffizienz und Garantieumfang

Bewerten Sie Bausätze anhand von drei zentralen Faktoren:

- Materialhaltbarkeit : Strukturierte Dämmplatten (SIPs) reduzieren Wärmebrücken um 15–25 % im Vergleich zu herkömmlichen Holzrahmenkonstruktionen (National Home Builders Association 2023)

- Energieeffizienz : Fenster und Türen mit ENERGY STAR-Zertifizierung können die jährlichen Heizkosten um 18–22 % senken

- Garantiebedingungen : Wählen Sie Kits mit mehr als 10 Jahren struktureller Garantie und 2–5 Jahren für mechanische Systeme

Zusammenarbeit mit Herstellern: Nutzung von Katalogen und Designunterstützung

Führende Hersteller bieten heute Online-Kataloge mit interaktiven 3D-Modellen an, die Kunden dabei helfen, zu erkennen, wie verschiedene Komponenten räumlich zusammenpassen und wie unterschiedliche Oberflächenoptionen aussehen. Es lohnt sich auch, Beratungsgespräche zu vereinbaren, da diese Fragen zur Bauzeit klären und ortspezifische Probleme angehen können, beispielsweise den Umgang mit starken Küstenwinden oder das Bauen auf unebenem, bergigem Gelände. Ein kürzlich erschienener Bericht aus der modularen Bauindustrie aus dem Jahr 2024 zeigte etwas Interessantes: Fast alle (etwa 92 %) derjenigen, die sich die Zeit nahmen, mindestens drei verschiedene Hersteller-Websites zu besuchen, fühlten sich deutlich sicherer hinsichtlich der Genauigkeit ihrer Planungen und hatten später weniger unerwartete Kosten.

Abwägung zwischen individueller Anpassung und Kosteneffizienz sowie Produktionseffizienz

Sonderausstattungen wie gewölbte Decken oder maßgefertigte Möbel verlängern die Produktionszeit in der Regel um 7–10 Tage. Standardisierte Designs kosten 12–18 % weniger als vollständig individuelle Lösungen, behalten jedoch ihre Leistungsfähigkeit bei. Nutzen Sie vordefinierte Upgrade-Pakete – wie „Luxus-Küche“ oder „Ganzjahres-Isolierung“ –, um Ihr Zuhause effizient und innerhalb des Budgets zu personalisieren.

FAQ

Was sind Modulhaus-Bausätze?

Modulhaus-Bausätze sind vorgefertigte Pakete, die alle notwendigen Komponenten wie tragende Strukturen, Außen- und Innenbereiche zum Bau eines Modulhauses enthalten.

Können modulare Häuser individuell gestaltet werden?

Ja, Modulhäuser bieten Anpassungsmöglichkeiten bei Möbelfinishes, Außenfarben, Fensterplatzierungen und Raumgrößen, wobei umfangreiche Anpassungen die Lieferzeiten beeinträchtigen können.

Welche Arten von Fundamenten werden für Modulhäuser verwendet?

Modulhäuser können auf Platten, Kriechkellern oder Vollkellern errichtet werden, angepasst an die örtlichen Gegebenheiten und klimatischen Anforderungen.

Sind modulare Häuser energieeffizient?

Modulhäuser verfügen in der Regel über energieeffiziente Komponenten, darunter Fenster mit ENERGY STAR-Zertifizierung und isolierte Stahltüren, wodurch die Heizkosten erheblich gesenkt werden.

Inhaltsverzeichnis

- Was ist in modularen Hausbausätzen enthalten: Kernkomponenten und Standardleistungen

-

Außen- und Innenausstattung: Materialien, Qualität und Anpassungsmöglichkeiten

- Außenbauteile: Fassadenverkleidung, Dach, Fenster und Türen – Haltbarkeit und Energieeffizienz

- Innenverkleidungen: Wände, Fußböden, Zierleisten und Einbaumöbel

- Küchen- und Badezimmergrundrisse: Vorgefertigt für Effizienz und Funktionalität

- Möglichkeiten zur Individualisierung: Ausgewogenes Verhältnis zwischen persönlichen Designwünschen und serienmäßiger Fertigung

- Gründung und Baustellenvorbereitung: Die Voraussetzungen für die Installation eines Fertighauses schaffen

-

Der Bauprozess: Lieferung, Montage und abschließende Inspektionen

- Logistik der Lieferung von Modulhaus-Bausätzen zur Baustelle

- Montage vor Ort: Verbindung der Module und Abdichtung der Fugen zur Gewährleistung der strukturellen Integrität

- Endgültige Fertigstellung: Anschluss der Versorgungsleitungen, Inspektionen und Bereitstellung für den Einzug

- Berücksichtigung von Bedenken: Strukturelle Leistung und langfristige Haltbarkeit nach der Montage

-

So wählen Sie das richtige Modulhaus-Set für Ihre Bedürfnisse

- Bewertung von Grundrissen und Skalierbarkeit für zukünftige Erweiterungen

- Vergleich von Materialqualität, Energieeffizienz und Garantieumfang

- Zusammenarbeit mit Herstellern: Nutzung von Katalogen und Designunterstützung

- Abwägung zwischen individueller Anpassung und Kosteneffizienz sowie Produktionseffizienz

- FAQ